Dekozell® FOR ARCHITECTS AND BUILDERS

Your acoustic plaster solution. Promoting a new freedom.

Nothing can go wrong. And if it does, it doesn’t matter.

Best room acoustics.

Precisely tailored to your architecture.

DEKOZELL® brings more to the acoustic ceiling than ever before. The invisible repairability of the beautiful white, smooth DEKOZELL® surface is the long-term guarantee for architects and building owners that they have made the right decision. Because when it comes to an aesthetic and sustainable high-performance acoustic plaster solution, only a DEKOZELL® acoustic ceiling or wall really makes sense.

Smooth. White. Seamless. As if it wasn’t there.

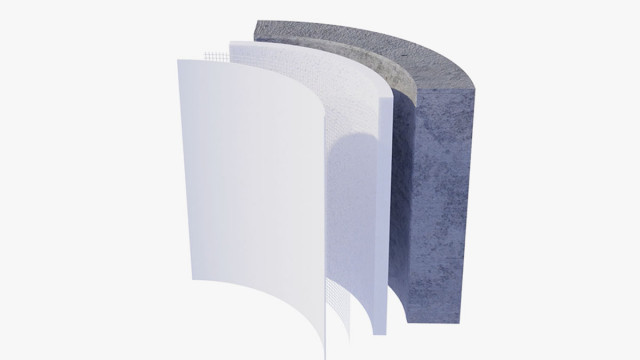

Unlimited possibilities. Infinitely mouldable.

Our systems were developed from the outset to prioritise safety and ease of application. We have simply completely rethought acoustic plaster. We use natural fibres as a filler instead of mineral particles. Plant fibres such as cellulose and cotton are ecological as renewable raw materials. And they make DEKOZELL® acoustic plaster so incredibly tough.

- Unlimited design possibilities

- Extreme user safety

- Re-coat & invisibly repair at any time

- Can be renovated an unlimited number of times

Every ceiling. Every wall. Every project.

Perfectly shaped for great architecture.

Our projects for particularly demanding customers such as the Elbphilharmonie concert hall, the ORF Viennas’ recording studios and the owners of magnificent private villas are proof of our high performance. And have impressed architects, fabricators and building owners alike with their reliable, wide-ranging system diversity. The sophisticated system features give you the opportunity to fulfil more acoustic project requirements more easily than ever before. And whatever you can imagine, your favorite painting company can make it happen.

Simply attach our systems to the painter’s specifications during the tendering phase. The best installer for DEKOZELL® systems is the tradesman who is on site anyway. The system is created step by step – and during the intermediate drying periods, the tradesman simply does the other work on the building site. We have 95% first-time installers – with an error rate of pretty much 0%. We guide your craftsman safely to his goal.

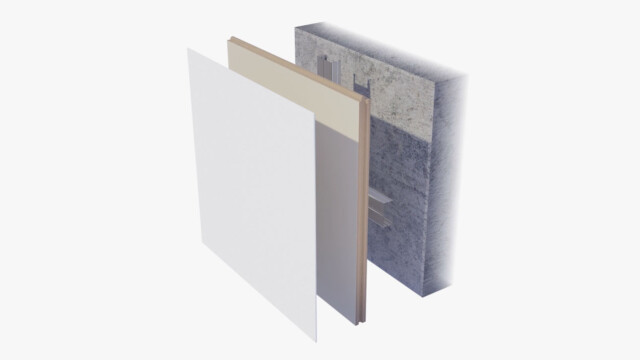

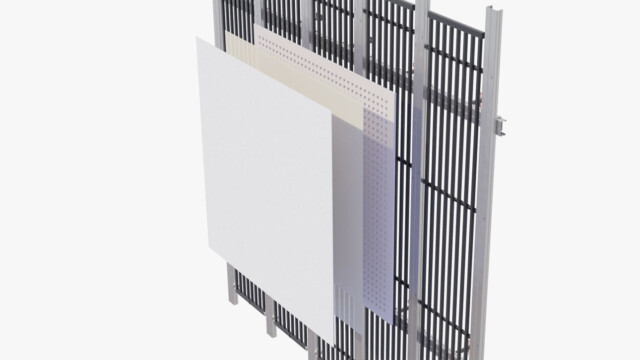

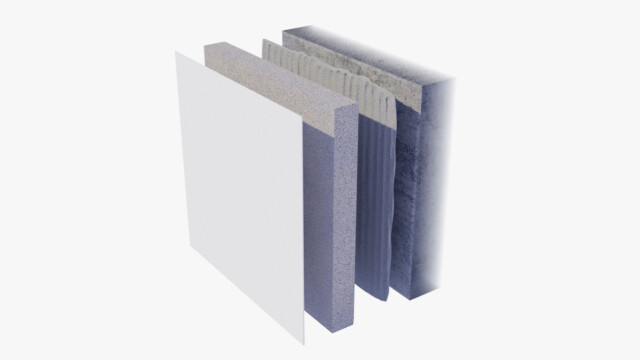

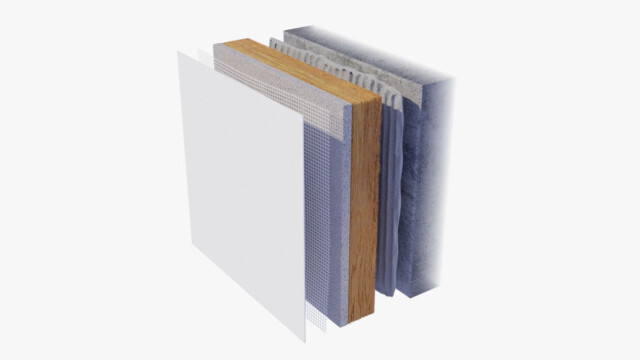

DEKOZELL® Acoustic plaster systems

The right system for every project.

The well thought-out variety of our systems enables perfect room acoustics to be seamlessly integrated into all conceivable buildings, halls and rooms. Configure your DEKOZELL acoustic plaster system according to your requirements. If you do not know exactly which system is suitable, we will be happy to help you.

Let us convince you

and inspire you.

Let us advise you

Talk to our Dekozell specialists. We “only” make seamless acoustic plaster systems, but we do it uniquely well and with enthusiasm. And we go the extra mile for you to find the best solution for your project.

Request a free sample

Only your professional judgement decides. So request your product sample from us and take the Dekozell quality check into your own hands. We will ensure that you receive your sample as quickly as possible.

Frequently Asked Questions (FAQ)

We frequently receive similar questions about acoustic plaster, acoustic ceilings and DEKOZELL in general. Here, we have summarised our answers for you.

Seamless acoustic plaster systems are still a niche product. Most acoustic ceilings are installed as visible solutions, e.g. as perforated panels with visible holes or as grid cassette ceilings with visible 60×60 insert panels. We only make seamless and therefore invisible acoustic ceilings. Our smooth acoustic plaster coating is visually indistinguishable from a smoothly levelled ceiling – and therefore invisible. We are at home in concealment.

Directly from us. Because every project is an important multiplier for all of us and should be a perfect success. As an acoustic plaster is much more complex than a bag of cement, we seek to be close to the installer. In our experience, this is the only way to provide the necessary support during processing.

For very large projects, we use your trusted building materials dealer as an invoicing partner in exceptional cases. And there are dealers who are really committed and very active in providing advice. Feel free to ask us, we have a sensible solution for everything.

Basically, any painter. Our systems have been developed from the outset to prioritise safety and ease of application. DEKOZELL FLEXOPANEL is as simple as wallpapering. DEKOZELL DISTANCE-EASY is like hanging with a normal plasterboard ceiling. Any drywall installer can do it. Added to this are extremely long open times for plaster application, sandability and the possibility of making invisible repairs. Add to this our step-by-step work instructions and intensive site support with short video calls for each work step: DEKOZELL creates completely smooth acoustic ceilings with a net and double bottom.

Absolutely. Renovation and invisible repairs are the key. Damage to the ceiling? Forgotten emergency lighting? Dirt? No problem? Instead of tearing everything down again, a DEKOZELL ceiling can also be partially repaired invisibly. If it’s done right, you won’t be able to find a repair even in the middle of the surface in the color white. Craftsmen can get started directly on the construction site without extensive training.

Technically speaking, one man alone can coat any size of surface. A break can be taken at any time in the middle of the surface, even overnight. Instead of a complex surface scaffold, a normal rolling scaffold is sufficient. This means that every trade business can open up a new and lucrative area of business. Architects simply attach the DEKOZELL acoustic plaster system to the normal painting tender. Exciting? Find out more here

The absolutely invisible repairability of the smooth white final surface is your life insurance in the project. If dust deposits appear over the years around ventilation outlets, for example, we simply polish them away. Do you know of any other manufacturer who can do this? But even during the construction phase, it’s almost certain that someone will damage something: a scaffolding pole or a ladder will hit the ceiling, a corner of the cupboard will be knocked into the ceiling when installing the built-in cupboards – or the ladder will tip over when installing the lighting: fortunately, the other hand can still just “grab” the ceiling – but unfortunately there was aluminium dust from the ladder on the hand. Nobody wants these souvenirs.

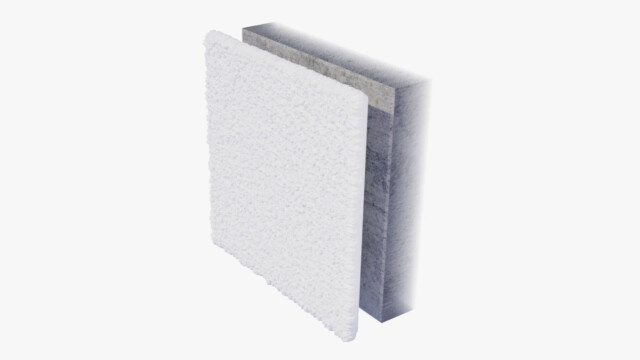

We have completely rethought acoustic plaster. Most other manufacturers’ acoustic plasters are mineral-based. However, a mineral is actually an airtight filler. Only through special processing can a mineral filler be used to create a plaster surface that is ultimately also permeable to air. This explains the susceptibility to defects of standard mineral acoustic plasters, which use airtight mineral particles as a filler. We use natural fibres as a filler instead of mineral particles. As renewable raw materials, plant fibres such as cellulose and cotton are not only more ecological – they are also highly permeable to air.

So, we have a filler that is already naturally permeable to air. And therein lies the secret. We disperse this filler for the plaster with approx. 80% water. The water evaporates and leaves behind air-permeable micropores in our already air-permeable filler. With classic mineral acoustic plasters, the micropores have to be created using special tactics during processing–and this means that errors are already pre-programmed. Our completely different technological approach is the reason for the ingenious workability and repairability of our acoustic plasters. And we have the patent for the use of natural fibres as a filler in acoustic plasters.

We “only” make seamless acoustic plaster systems. But we do it well and with enthusiasm! For us, an acoustic plaster system is not just something that we have to have in our portfolio in case someone doesn’t want to see any holes in the perforated panel. Or that someone who usually buys thermal insulation happens to ask for. Acoustic plaster systems are our life. Put us to the test.