Dekozell® PARTNER COMPANIES

Perfect acoustic plaster. In the hands of the best.

Dekozell® INSIDE. GOOD FOR YOUR BUSINESS.

The best project partners for your success.

Who can and may process DEKOZELL®? Anyone can if they want to! And anyone who really wants to will surpass themselves with us. For sure. Because the craftsman who will be on the building site anyway is usually the best person to install our systems. Due to the intermediate drying, the long open times and the sandability, there is only one step at a time per day anyway. Our favorite tradespeople are often the ones who are a little apprehensive at first, the reserved ones, the ones who think along with us. Over 90 per cent of our projects are carried out by first timers. With virtually 0 per cent error rate. Once you have worked with DEKOZELL®, you usually stay with us forever.

A partner, as we see it, is a completely different level. A partner doesn’t just process our systems, they put their heart and soul and their own investment behind DEKOZELL®. He is a doer, an innovator, a multiplier, a rock in the surf. With a demand for perfect craftsmanship, attention to detail and an unconditional desire to delight customers. We would be delighted to introduce you to our partner companies here, for whom we put our money where our mouth is – and who simply tick like we do. Down-to-earth, honest and reliable.

STEUERNAGEL & LAMPERT

5,000m² acoustic ceiling and walls for a museum

Steuernagel & Lampert, also known as “Steula” for short, is a traditional yet innovative family business. Their expertise already plays an important role in the intensive communication and consultation: whether private customer or industrial order, public works, or specialised architectural projects–”Steula” has the right contact person directly at hand. Our partner also perfectly realised the Reinhard Ernst Museum in Wiesbaden with 5,000m² of DEKOZELL®. And presents a DEKOZELL® heating/cooling/acoustic ceiling in its showroom.

- Steuernagel & Lampert, Groß-Bieberau

- Phone +49 6162 91 17 80

- www.steula.com

POLYCHROM JEHLE

The master of colors makes the difference

polychrom JEHLE holds the “Master of Colors” certificate from the color manufacturer kt.COLOR. And therefore stands not only for a variety of colors, but also for the conscious staging of your uniqueness. The painting company develops color concepts and uses sensitivity and aesthetics to develop surfaces that emphasise uniqueness. We have never met Harald Jehle in person. But he is so convinced of DEKOZELL® that he has built a showroom–with a DEKOZELL® acoustic ceiling, wonderfully colorful and blending perfectly with the wall color.

- polychrom JEHLE, Weingarten

- Phone +49 751 569 32 39

- www.polychrom-jehle.de

DEKOZELL® ACOUSTIC PLASTER SYSTEMS

References

It is the acousticians, architects and craftsmen, who together make our success stories possible. With their demand for the highest quality materials and support, to enable them to create the perfect solution.

Discover with us a selection of the acoustic plaster projects that we have together achieved in a variety of challenging applications.

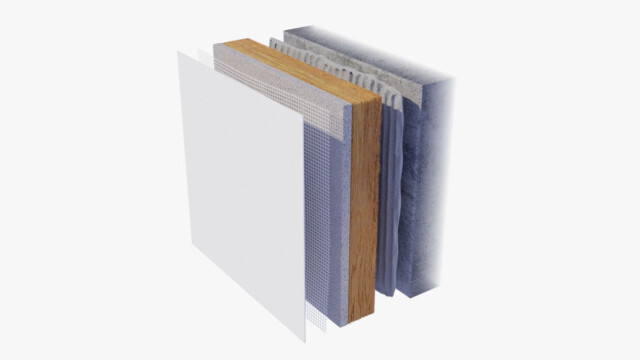

DEKOZELL® Acoustic plaster systems

The right system for every project.

The well thought-out variety of our systems enables perfect room acoustics to be seamlessly integrated into all conceivable buildings, halls and rooms. Configure your DEKOZELL acoustic plaster system according to your requirements. If you do not know exactly which system is suitable, we will be happy to help you.

Let us convince you

and inspire you.

Let us advise you

Talk to our Dekozell specialists. We “only” make seamless acoustic plaster systems, but we do it uniquely well and with enthusiasm. And we go the extra mile for you to find the best solution for your project.

Request a free sample

Only your professional judgement decides. So request your product sample from us and take the Dekozell quality check into your own hands. We will ensure that you receive your sample as quickly as possible.

Frequently Asked Questions (FAQ)

We frequently receive similar questions about acoustic plaster, acoustic ceilings and DEKOZELL in general. Here, we have summarised our answers for you.

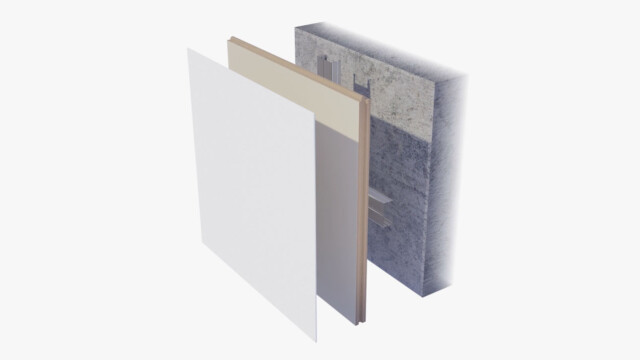

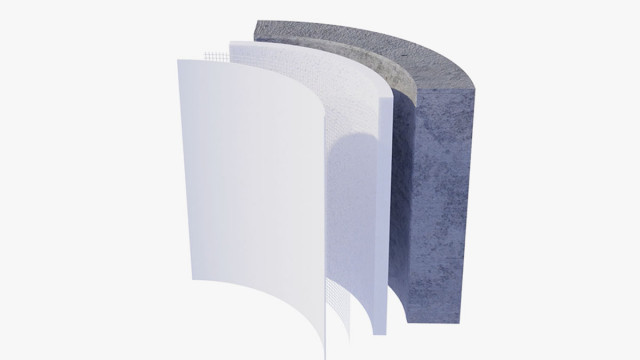

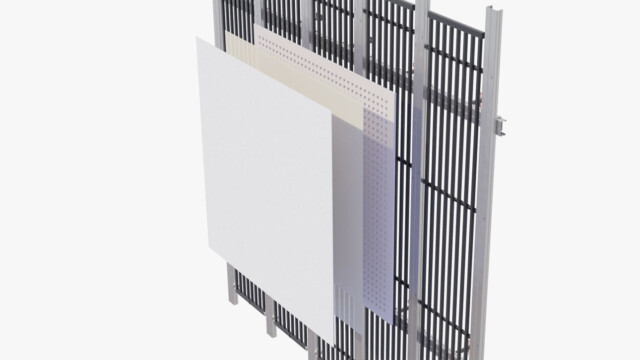

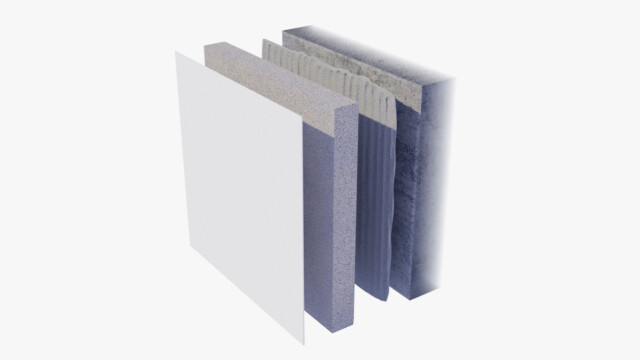

Seamless acoustic plaster systems are still a niche product. Most acoustic ceilings are installed as visible solutions, e.g. as perforated panels with visible holes or as grid cassette ceilings with visible 60×60 insert panels. We only make seamless and therefore invisible acoustic ceilings. Our smooth acoustic plaster coating is visually indistinguishable from a smoothly levelled ceiling – and therefore invisible. We are at home in concealment.

Directly from us. Because every project is an important multiplier for all of us and should be a perfect success. As an acoustic plaster is much more complex than a bag of cement, we seek to be close to the installer. In our experience, this is the only way to provide the necessary support during processing.

For very large projects, we use your trusted building materials dealer as an invoicing partner in exceptional cases. And there are dealers who are really committed and very active in providing advice. Feel free to ask us, we have a sensible solution for everything.

Basically, any painter. Our systems have been developed from the outset to prioritise safety and ease of application. DEKOZELL FLEXOPANEL is as simple as wallpapering. DEKOZELL DISTANCE-EASY is like hanging with a normal plasterboard ceiling. Any drywall installer can do it. Added to this are extremely long open times for plaster application, sandability and the possibility of making invisible repairs. Add to this our step-by-step work instructions and intensive site support with short video calls for each work step: DEKOZELL creates completely smooth acoustic ceilings with a net and double bottom.

Absolutely. Renovation and invisible repairs are the key. Damage to the ceiling? Forgotten emergency lighting? Dirt? No problem? Instead of tearing everything down again, a DEKOZELL ceiling can also be partially repaired invisibly. If it’s done right, you won’t be able to find a repair even in the middle of the surface in the color white. Craftsmen can get started directly on the construction site without extensive training.

Technically speaking, one man alone can coat any size of surface. A break can be taken at any time in the middle of the surface, even overnight. Instead of a complex surface scaffold, a normal rolling scaffold is sufficient. This means that every trade business can open up a new and lucrative area of business. Architects simply attach the DEKOZELL acoustic plaster system to the normal painting tender. Exciting? Find out more here

The absolutely invisible repairability of the smooth white final surface is your life insurance in the project. If dust deposits appear over the years around ventilation outlets, for example, we simply polish them away. Do you know of any other manufacturer who can do this? But even during the construction phase, it’s almost certain that someone will damage something: a scaffolding pole or a ladder will hit the ceiling, a corner of the cupboard will be knocked into the ceiling when installing the built-in cupboards – or the ladder will tip over when installing the lighting: fortunately, the other hand can still just “grab” the ceiling – but unfortunately there was aluminium dust from the ladder on the hand. Nobody wants these souvenirs.

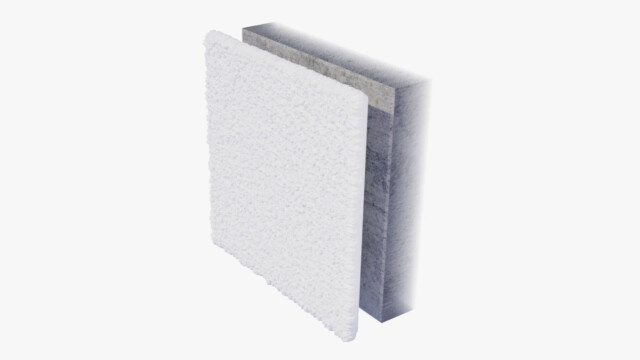

We have completely rethought acoustic plaster. Most other manufacturers’ acoustic plasters are mineral-based. However, a mineral is actually an airtight filler. Only through special processing can a mineral filler be used to create a plaster surface that is ultimately also permeable to air. This explains the susceptibility to defects of standard mineral acoustic plasters, which use airtight mineral particles as a filler. We use natural fibres as a filler instead of mineral particles. As renewable raw materials, plant fibres such as cellulose and cotton are not only more ecological – they are also highly permeable to air.

So, we have a filler that is already naturally permeable to air. And therein lies the secret. We disperse this filler for the plaster with approx. 80% water. The water evaporates and leaves behind air-permeable micropores in our already air-permeable filler. With classic mineral acoustic plasters, the micropores have to be created using special tactics during processing–and this means that errors are already pre-programmed. Our completely different technological approach is the reason for the ingenious workability and repairability of our acoustic plasters. And we have the patent for the use of natural fibres as a filler in acoustic plasters.

We “only” make seamless acoustic plaster systems. But we do it well and with enthusiasm! For us, an acoustic plaster system is not just something that we have to have in our portfolio in case someone doesn’t want to see any holes in the perforated panel. Or that someone who usually buys thermal insulation happens to ask for. Acoustic plaster systems are our life. Put us to the test.