Dekozell® PROCESSING

Processing guidelines

To ensure that everything goes well

Service, security and much, much more

With the Dekozell system nothing will go wrong providing you adhere to the installation processes and product data sheets. Observing the relevant technical specification, information and approvals of the products.

No offence intended: Applicability and completeness must be checked by the installer and customer; their own responsibility must be taken for the proposed construction project. All specifications and information must be adapted to conform to local regulations.

Likewise, all information provided does not replace detailed work or installation planning. No matter what: Dekozell is ready to advise and help in all aspects of your project. In case of any concern or query we are on hand remotely to assist, as and when you need us. If in doubt, please contact us.

BENEFITS

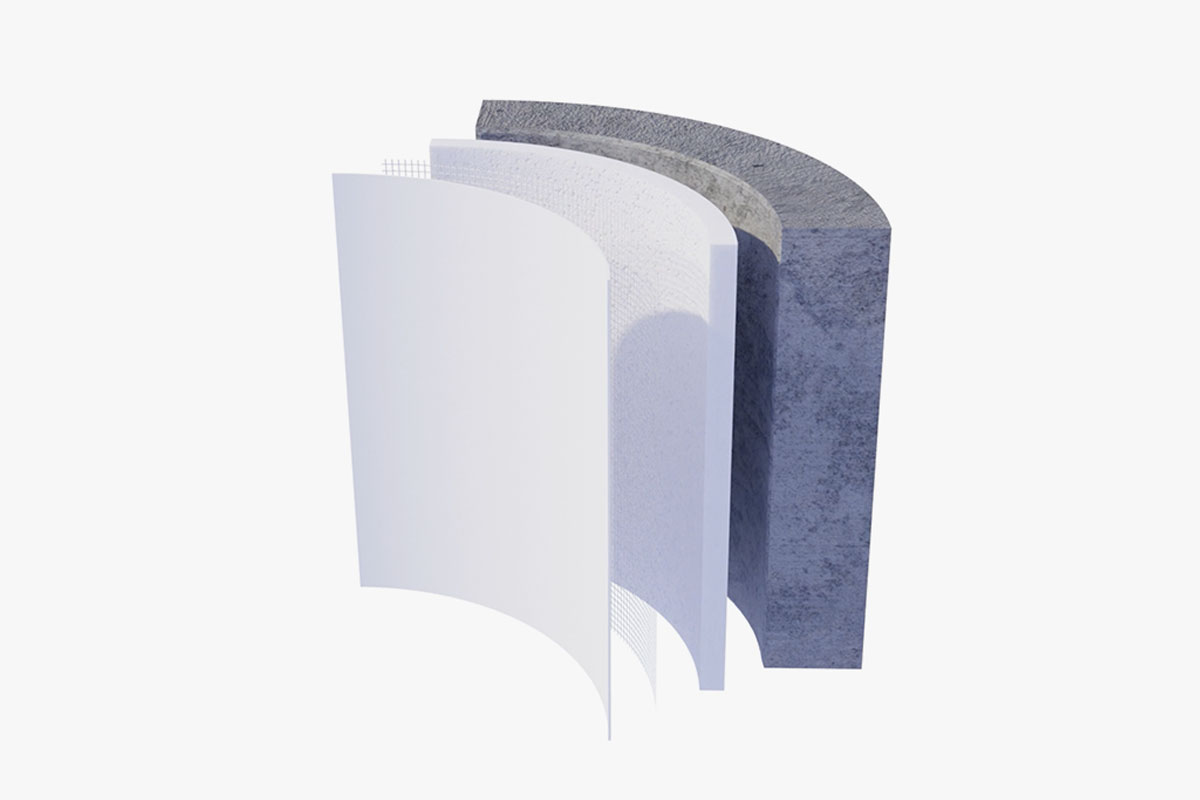

DEKOZELL® SYSTEM FLEXO-PANEL

Our best-selling system: very flat, light as a feather, uniquely sound absorbing. Simply wallpaper walls and ceilings, even in swimming pools.

BENEFITS

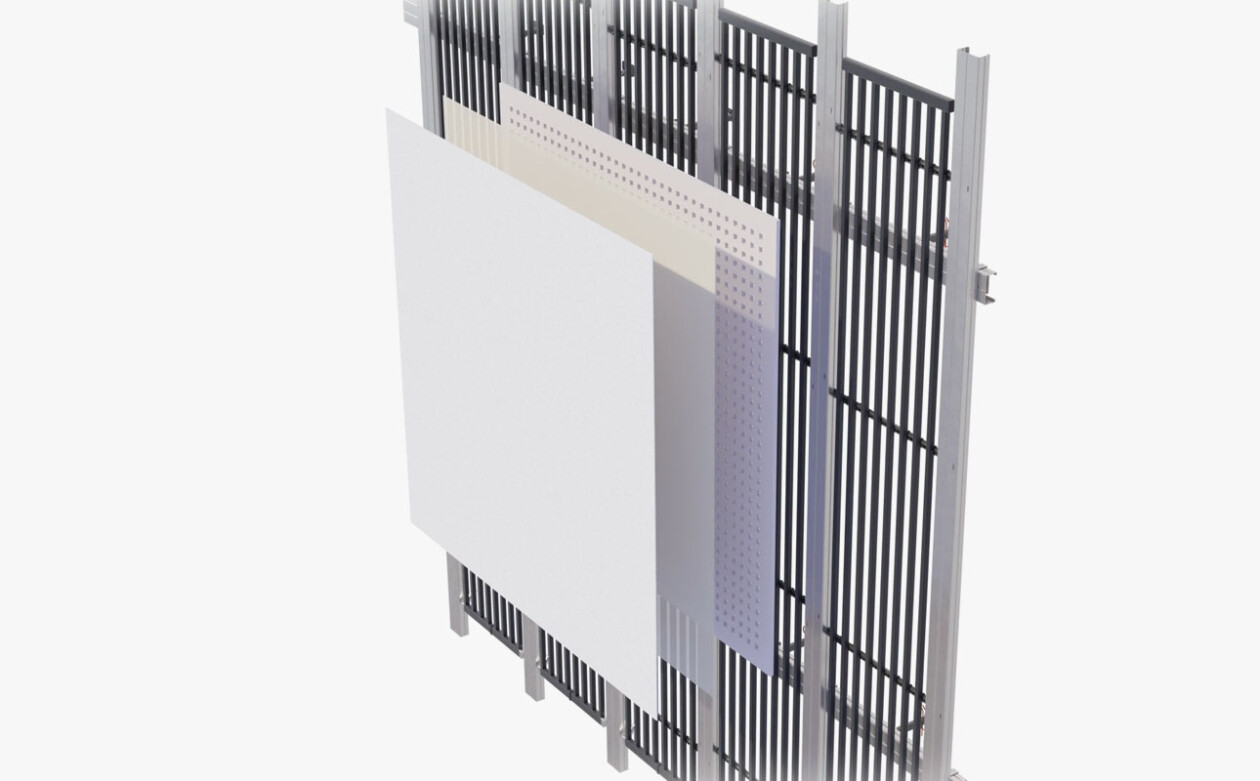

DEKOZELL® SYSTEM GK-Loch

Turn any GK perforated panel into a seamlessly smooth heating/cooling acoustic ceiling. Even ball-proof for sports and multi-purpose halls.

BENEFITS

DEKOZELL® SYSTEM ROBUST

Ball-proof, even for walls: maximum impact resistance, installation depth of up to 5 cm for spotlights and cables, suitable for swimming pools and weathered outdoor areas.

BENEFITS

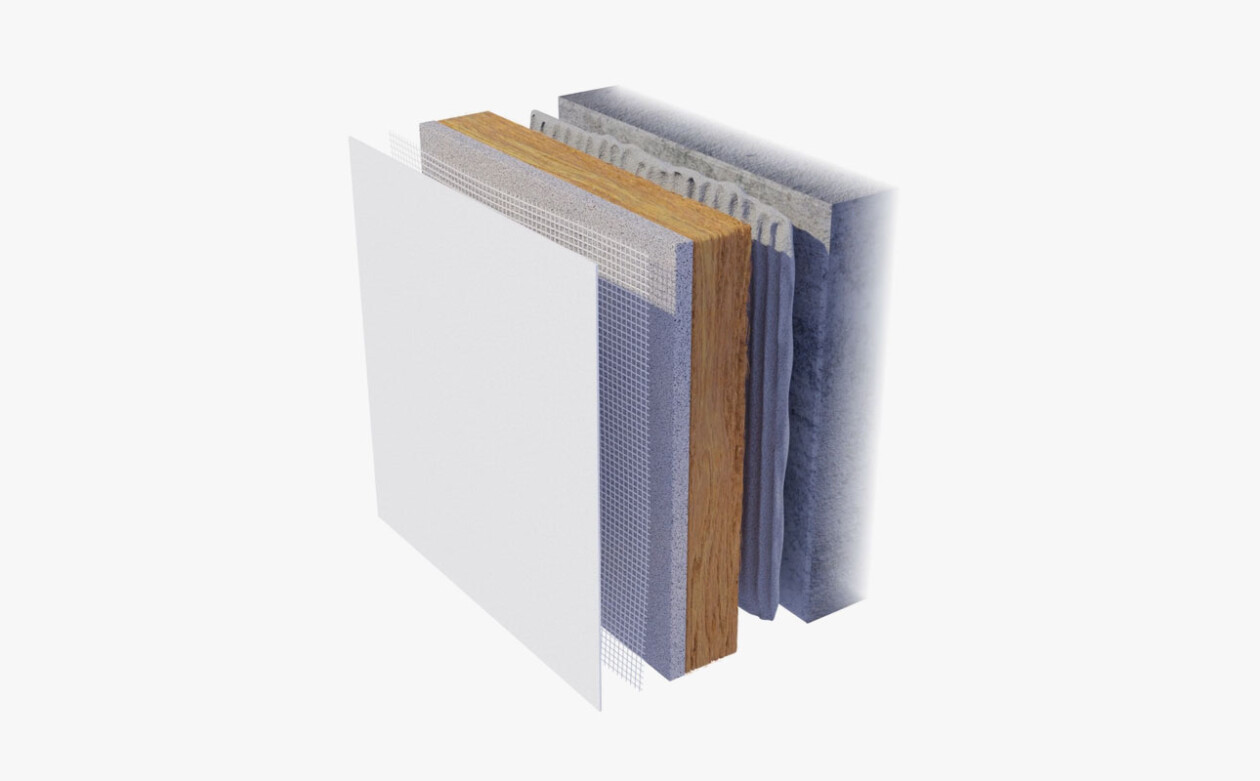

DEKOZELL® SYSTEM MAXISWING

Anyone who likes mineral wool will get their money’s worth here. The all-rounder for heat and sound insulation. Up to 5 cm installation depth for spotlights and cables, not suitable for swimming pools or external walls.

BENEFITS

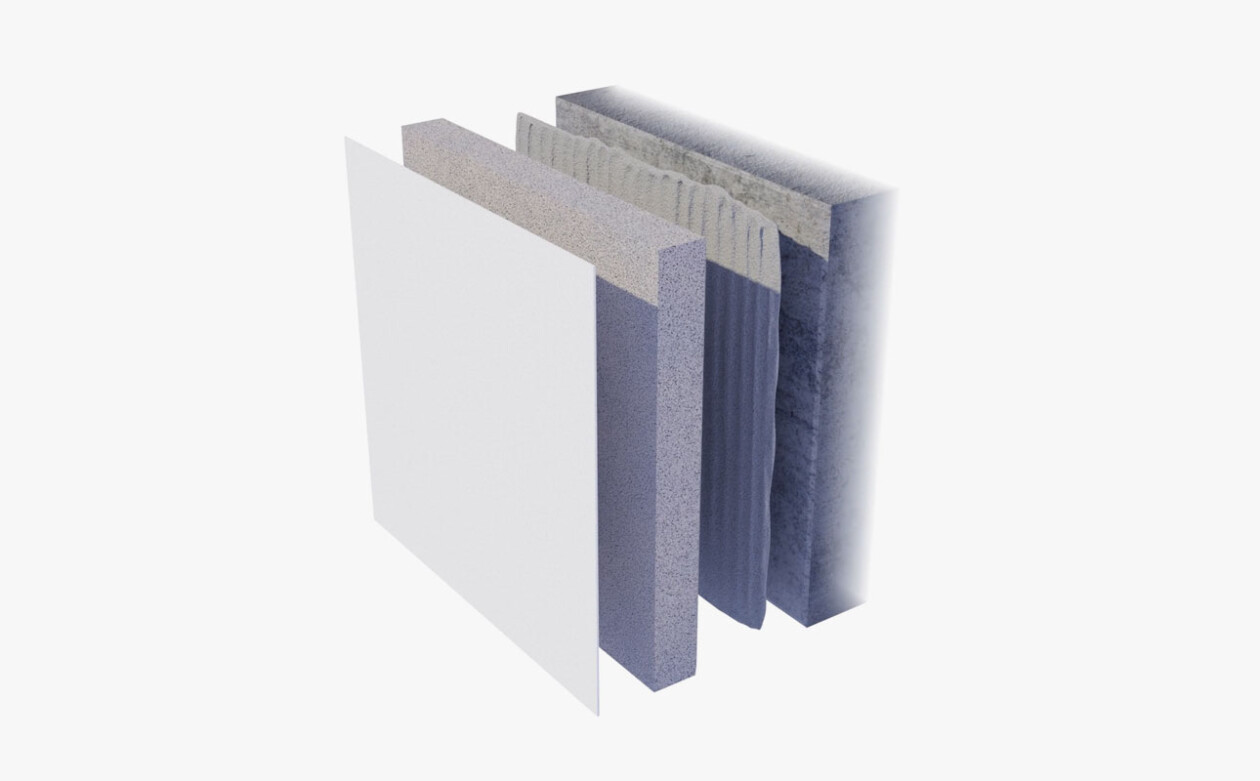

DEKOZELL® SYSTEM MODERAT

Prime, spray on, done. Inexpensive, possible on very uneven substrates. For revitalised rough surfaces, popular in brutalist architecture such as the industrial look or on unplastered concrete.

ACOUSTIC PLASTER SYSTEMS RETHOUGHT

Do you have any questions? Give us a call!

This might also interest you.

Acoustic Spray Plaster

Specially developed for easy spraying of smooth and seamless surfaces. As a final coating for our smart coating systems, it provides a huge leap in performance and possibilities.

Our systems

Systematically more possibilities. Acoustic ceilings, straight and curved walls, perfect edge finishes or curved domes can be provided with acoustic coatings more reliably than ever before.

Frequently Asked Questions (FAQ)

We frequently receive similar questions about acoustic plaster, acoustic ceilings and DEKOZELL in general. Here, we have summarised our answers for you.

Seamless acoustic plaster systems are still a niche product. Most acoustic ceilings are installed as visible solutions, e.g. as perforated panels with visible holes or as grid cassette ceilings with visible 60×60 insert panels. We only make seamless and therefore invisible acoustic ceilings. Our smooth acoustic plaster coating is visually indistinguishable from a smoothly levelled ceiling – and therefore invisible. We are at home in concealment.

Directly from us. Because every project is an important multiplier for all of us and should be a perfect success. As an acoustic plaster is much more complex than a bag of cement, we seek to be close to the installer. In our experience, this is the only way to provide the necessary support during processing.

For very large projects, we use your trusted building materials dealer as an invoicing partner in exceptional cases. And there are dealers who are really committed and very active in providing advice. Feel free to ask us, we have a sensible solution for everything.

Basically, any painter. Our systems have been developed from the outset to prioritise safety and ease of application. DEKOZELL FLEXOPANEL is as simple as wallpapering. DEKOZELL DISTANCE-EASY is like hanging with a normal plasterboard ceiling. Any drywall installer can do it. Added to this are extremely long open times for plaster application, sandability and the possibility of making invisible repairs. Add to this our step-by-step work instructions and intensive site support with short video calls for each work step: DEKOZELL creates completely smooth acoustic ceilings with a net and double bottom.

Absolutely. Renovation and invisible repairs are the key. Damage to the ceiling? Forgotten emergency lighting? Dirt? No problem? Instead of tearing everything down again, a DEKOZELL ceiling can also be partially repaired invisibly. If it’s done right, you won’t be able to find a repair even in the middle of the surface in the color white. Craftsmen can get started directly on the construction site without extensive training.

Technically speaking, one man alone can coat any size of surface. A break can be taken at any time in the middle of the surface, even overnight. Instead of a complex surface scaffold, a normal rolling scaffold is sufficient. This means that every trade business can open up a new and lucrative area of business. Architects simply attach the DEKOZELL acoustic plaster system to the normal painting tender. Exciting? Find out more here

The absolutely invisible repairability of the smooth white final surface is your life insurance in the project. If dust deposits appear over the years around ventilation outlets, for example, we simply polish them away. Do you know of any other manufacturer who can do this? But even during the construction phase, it’s almost certain that someone will damage something: a scaffolding pole or a ladder will hit the ceiling, a corner of the cupboard will be knocked into the ceiling when installing the built-in cupboards – or the ladder will tip over when installing the lighting: fortunately, the other hand can still just “grab” the ceiling – but unfortunately there was aluminium dust from the ladder on the hand. Nobody wants these souvenirs.

We have completely rethought acoustic plaster. Most other manufacturers’ acoustic plasters are mineral-based. However, a mineral is actually an airtight filler. Only through special processing can a mineral filler be used to create a plaster surface that is ultimately also permeable to air. This explains the susceptibility to defects of standard mineral acoustic plasters, which use airtight mineral particles as a filler. We use natural fibres as a filler instead of mineral particles. As renewable raw materials, plant fibres such as cellulose and cotton are not only more ecological – they are also highly permeable to air.

So, we have a filler that is already naturally permeable to air. And therein lies the secret. We disperse this filler for the plaster with approx. 80% water. The water evaporates and leaves behind air-permeable micropores in our already air-permeable filler. With classic mineral acoustic plasters, the micropores have to be created using special tactics during processing–and this means that errors are already pre-programmed. Our completely different technological approach is the reason for the ingenious workability and repairability of our acoustic plasters. And we have the patent for the use of natural fibres as a filler in acoustic plasters.

We “only” make seamless acoustic plaster systems. But we do it well and with enthusiasm! For us, an acoustic plaster system is not just something that we have to have in our portfolio in case someone doesn’t want to see any holes in the perforated panel. Or that someone who usually buys thermal insulation happens to ask for. Acoustic plaster systems are our life. Put us to the test.